Transformer oil purification involves purifying transformer oil to eliminate contaminants, moisture, and gases. This process ensures the oil retains its insulating and cooling properties. Clean transformer oil plays a critical role in maintaining the efficiency and safety of a transformer. It also prevents overheating and electrical breakdowns, which can lead to costly failures.

What is Transformer Oil Purification?

Transformer oil, also known as insulating oil, is a specialized mineral oil used in electrical transformers to insulate and cool the transformer’s internal components. It plays a crucial role in maintaining the efficiency and safety of transformers by preventing overheating and reducing the risk of electrical arcing.

Transformer oil is primarily composed of hydrocarbon compounds and is designed to withstand high temperatures and electrical stresses. It also serves to dissipate heat generated during transformer operation, ensuring stable performance.

Transformer oil purification is a process that removes impurities, moisture, and gas from used transformer oil to restore its insulating properties. Over time, transformer oil can degrade due to the presence of contaminants, which can negatively affect its performance and the overall reliability of the transformer. This process extends the lifespan of the oil and ensures that transformers continue to operate efficiently and safely.

Why Transformer Oil Filtration is Important

Maintains Electrical Insulation Properties

Transformer oil plays a vital role in insulating electrical components. Over time, contaminants such as moisture, dirt, and dissolved gases can degrade its insulating properties. Transformer oil filtration removes these impurities, ensuring the oil maintains its ability to prevent electrical discharges.

Clean oil reduces the risk of short circuits and enhances the overall safety of the transformer. Regular transformer oil testing helps identify when filtration is necessary to preserve insulation quality.

Prevents Transformer Failures

Contaminated transformer oil can lead to overheating and electrical breakdowns. These issues often result in costly transformer failures. The oil filtration procedure eliminates harmful particles and moisture, reducing the likelihood of such failures.

Transformer oil filtration and dehydration processes are particularly effective in addressing water contamination, which is a common cause of transformer malfunctions. By keeping the oil clean, the risk of unexpected downtime decreases significantly.

Extends Transformer Lifespan

Transformers are long-term investments, and their lifespan depends on proper maintenance. Transformer oil purification ensures the oil remains in optimal condition, preventing wear and tear on internal components.

Filtration and dehydration processes remove corrosive elements that could damage the transformer over time. This proactive approach to maintenance extends the operational life of the equipment, saving costs in the long run.

Enhances Transformer Performance

Efficient transformers rely on clean oil for effective cooling and insulation. Contaminants in the oil can hinder heat dissipation, leading to reduced performance. Transformer oil conditioning through filtration improves the oil’s thermal conductivity, ensuring the transformer operates at peak efficiency. Using a transformer oil filtration machine as part of routine maintenance enhances the overall performance and reliability of the system.

When is Transformer Oil Filtration Required?

Signs of Contaminated Transformer Oil

Contaminated transformer oil can exhibit several warning signs. A noticeable change in color often indicates the presence of impurities. Dark or cloudy oil suggests contamination by moisture, dirt, or other particles. A strong or unusual odor may also signal chemical degradation.

Testing the oil’s dielectric strength can reveal reduced electrical insulation properties. High levels of dissolved gases or water content detected during routine analysis further confirm contamination. These signs highlight the need for transformer oil filtration to restore the oil’s quality and functionality.

Routine Maintenance Needs

Routine maintenance plays a crucial role in ensuring transformer reliability. Over time, contaminants such as moisture and gases accumulate in the oil, even under normal operating conditions. Regular transformer oil purification helps maintain optimal performance and prevents long-term damage.

Many operators schedule filtration as part of their preventive maintenance programs. Using a transformer oil filtration machine during these intervals ensures the oil remains clean and effective. This proactive approach minimizes the risk of unexpected failures and extends the transformer’s lifespan.

Post-Overload or Fault Conditions

Transformers subjected to overload or fault conditions often experience accelerated oil degradation. High temperatures during these events can lead to the formation of gases, sludge, and other contaminants. The oil’s insulating and cooling properties may deteriorate rapidly, increasing the risk of equipment failure.

In such cases, the oil filtration procedure becomes essential. Processes like dehydration of transformer oil and degassing remove moisture and gases, restoring the oil’s quality. Operators often rely on a transformer oil dehydration machine to address these issues effectively. Prompt action after such events ensures the transformer continues to operate safely and efficiently.

The Oil Purification Process

Key Steps in Transformer Oil Filtration

The oil filtration procedure involves several essential steps to restore the quality of transformer oil. The process begins with transformer oil testing to assess contamination levels. This step identifies impurities such as moisture, dissolved gases, and particles.

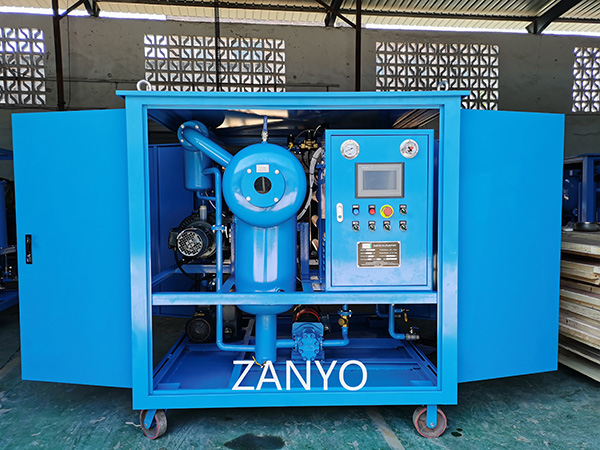

Next, the oil passes through a filtration system that removes solid contaminants. Degassing and dehydration follow, eliminating gases and water content. These steps ensure the oil regains its insulating and cooling properties. The power transformer oil filtration procedure concludes with quality checks to confirm the oil meets operational standards.

Transformer Oil Filtation and Dehydration

Transformer oil purification applies vacuum technology to extract moisture effectively. A transformer oil purification system is includes filters to remove solid particles, vacuum tank for degassing and moisture removal. This system also features a heater to enhance the filtration process. Operators can use mobile type oil purifer for on-site transformer oil processing.

Conclusion

Transformer oil purification plays a vital role in maintaining transformer reliability and performance. Regular filtration reduces maintenance costs and enhances safety by preventing failures. Clean oil ensures efficient operation and extends equipment lifespan. Prioritizing oil maintenance helps avoid costly repairs. Consulting professionals for proper servicing ensures transformers remain in optimal condition.