When transformer oil is contaminated the oil is loss of its dielectric properties, its stability is minimised, and the heat exchange is impaired by increasing viscosity. The dielectric oil purifier system is designed to eliminate gas, water and particulate matter from the oil thereby purifying it. You need a good Oil purifier system.

What is Dielectric Oil Purifier?

Transformers have an essential role within the power industry especially with electricity. Transformers transform appropriate levels of power to other componen of the system thereby safely using it. Transformers must be maintained to ensure long life. However, a clean and good quality oil is particularly important for this transformer to offer potential performance.

Transformer oil degrades with time. The exposed oil to unnecessary materials or components such as moisture, acids and metallic dust and so on. Whenever Transformers a comprise off dust, contaminants end gases that are dissolved in oil, it is essential to act for the purification and filtration of the oil.

Transformer services and maintenance centres sustain equipment of high-quality for treating oil. Transformer Filtration is used in filtration techniques of transformer oil. these applications assist in sustaining safety, excellent performance and operation simplicity for the staff.

Transformer oil and its functions

At extreme temps, transformer or insulating oil is usually stable. Aside from this one, insulating oil serves the following purposes:

As a cooler- When the voltage changes, the heat of its transformer’s windings rises, and oil is then used to lower the temperature.

As a barrier- Between the windings, it functions as an insulator. It prevents a short circuit by increasing the resistance between them.

For the sake of safety– It controls the amount of oil within the transformer. The oil temperature display indicates the transformer’s internal condition as well as any of the short circuits. As a result, you will avoid serious damage and losses to the transformer.

Types of Insulating oil

- Paraffin-based – obtained from specific crudes containing a significant quantity of n-paraffin. That insulating oil is much less oxidised unlike naphtha-based insulating oils.

- Naphtha-based – produced from specific crudes with just low n-paraffin content.

During the use of insulating oil, this could encounter materials that degrade its quality. Excessively high temperatures, oxidation, and other circumstances cause it to cease to function. As a result, the oil blackens in colour as well as the acid content starts to rise. Impurities in the oil are among top reasons of transformer failure. The insulating oil ought to be free of contaminants, debris, as well as moisture to prevent transformer breakdown. As a result, transformer oil filtering is required. Insulating oil gets checked but also treated inside this method to ensure that transformers perform properly.

How is transformer oil filtration system process?

With the use of a filtration apparatus, the process removes fine contaminated particles. The Purification and Drying Process warms the transformer oil to just a limit of 90 degrees Celsius and eliminates acidic as well as polar components. After that, there is a vacuum degassing procedure.

Transformers were among the most important assets throughout the electrical power business, and they must be maintained to provide continuous power transmission and predictable revenue.

The procedure and benefits of oil filtration system includes:

- Sludge, dissolved moisture, and dissolved gases are all removed from transformer oil during the purification process. Transformer oil conditioning may also entail reducing the acidity of the oil to

some amount. - The lifespan of something like a transformer is largely determined by the quality of the volume of the oil it holds.

- Filtration of transformer oil on a routine basis ensures the transformer’s longevity and consistency.

- Sludge, dissolved gases and dissolved moisture, are all removed from transformer oil during the filtration process. Transformer oil treatment also may entail reducing the acidity of said oil to a certain amount.

- A good oil filtration system can supply filtered oil with properties that meet industry standards.

- Purification of transformer oil is an issue that needs to be addressed.

- Transformer oil filtering is necessary to treat as well as cleanse insulating oil. Sediment and dampness are removed during the insulating oil purification process.

However, the grade of raw oil as well as its preliminary process determine the oil’s restoration to conventional oil criteria by an oil treatment plant. The work of transformer oil filtering will be in vain if the raw oil does not really fit the standard oil characteristics. In this instance, a different technique of transformer oil renewal should be used.

Purification of transformer oil has several advantages:

- The oil’s shielding characteristics have been improved.

- Transformers with a longer life

- Reduces the likelihood of a transformer failure. Having a high-quality machine pays off handsomely.

If the insulating oil does not go through this procedure, it can cause:

- Arcing is the creation like an electric arc that leads the system to fail.

- Oil overheating is one of the most common causes of overheating.

- Corona discharges are electrical discharges that occur when fluid is ionised.

- The transformer oil’s insulating effectiveness will deteriorate.

Fully various of transformer oil purifier supply

- The temperature of the oil is rising-The very first step would be to heat the oil to 65?C, that creates latent heat that divides moisture as well as gases. Due to the extreme reduction in oil viscosity, heated oil makes it much easier to cleanse.

- Dirt and pollutants are removed-The insulating oil must next be cleaned of sludge and grime. There are two methods for removing dirt from transformer oil.

- Filtering candles-Filter candles for insulating oil filtering could be classed as either a conventional edge filter or even a depth kind filter. However, significant developments have been made, including the use of filter cartridges rather than edge kind paper filters with transformer oil filtration equipment.

- The action of centrifugation-Centrifugation is another way for removing debris from oil. One could avoid the cost of replacing filters on a regular basis by using this method.

- Insulating oil degasification and dehydration-That’s the stage where the insulation oil is dehumidified,

- and gases are removed. In the degassing compartment, this procedure is done.

- The degradation of transformer oil must be kept to a minimum. According to studies, tainted oil is to blame for 80% of oil-related failures and breakdowns. As a result, preventive oil management is critical to ensuring maximum machine reliability.

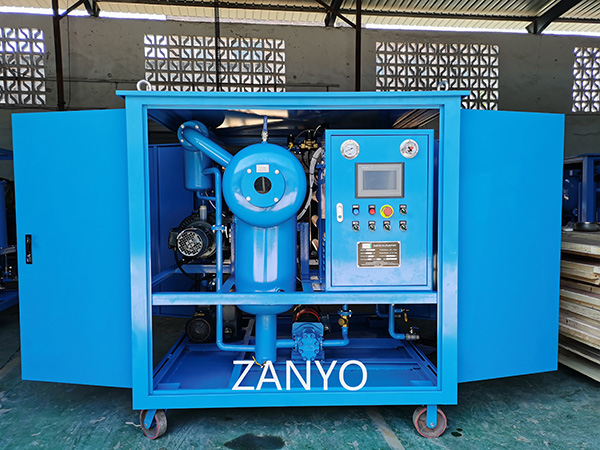

Quality Double-Stage Vacuum Oil Purifier for Sale

Filtration of transformer oil is extremely beneficial to any organisation. As a result, high-quality transformer oil filtering system is needed. There seem to be numerous companies that provide various types of equipment.

Choose a provider who produces high-quality insulating oil purification machines and can provide a good Return (ROI). The leading China manufacturer is particularly good in quality, diversity, stability in their service and affordable in their price.