Industrial oil purification plays a vital role in keeping machinery efficient and reducing operational expenses. Contaminants like water, gas, and particles can degrade oil quality, leading to equipment failures and costly repairs. By using advanced purification systems like those offered by ZANYO, you can maintain the performance of high-value machinery.

- The global oil purification machine market was valued at USD 1.2 billion in 2023.

- It is expected to grow to USD 2.8 billion by 2032, with a 9.4% CAGR.

- This growth highlights the increasing demand for maintaining machinery through quality oil purification solutions.

With ZANYO’s innovative machines, you ensure your oil remains clean and your operations run smoothly.

Key Takeaways

- Industrial oil cleaners help machines work better and save money.

- Various cleaners, like vacuum and centrifugal types, remove certain dirt to keep oil clean.

- Picking the right cleaner makes machines last longer and cost less to fix.

Types of Industrial Oil Purification Machines

Industrial oil purification machines come in various types, each designed to address specific contamination challenges. Understanding these types helps you select the most suitable solution for your operational needs.

Vacuum Oil Purification Machines

Vacuum oil purification machines are highly effective in removing water, gases, and solid contaminants from oil. These machines use vacuum technology to lower the boiling point of water and gases, allowing them to evaporate at lower temperatures. This process ensures that the oil retains its dielectric properties, making these machines ideal for transformer oil purification. For instance, High Vacuum Transformer Oil Purifier enhances equipment reliability by delivering clean and dry oil.

| Benefit | Description |

|---|---|

| Increased Equipment Reliability | Clean and dry turbine oil prolongs the lifespan of critical equipment. |

| Reduced Maintenance Costs | Predictive maintenance capabilities minimize unplanned downtime and reduce overall maintenance expenses. |

| Improved Operational Efficiency | Optimizing oil purification processes leads to greater energy efficiency and a reduced environmental footprint. |

Centrifugal Oil Purification Machines

Centrifugal oil purification machines use centrifugal force to separate contaminants like particulate matter and free water from oil. These machines are particularly effective for large industrial systems where high volumes of oil require purification. By spinning the oil at high speeds, the heavier contaminants are forced outward, leaving the purified oil in the center. This method is efficient and requires minimal maintenance, making it a popular choice for industries with heavy machinery.

Electrostatic Oil Purification Machines

Electrostatic oil purification machines utilize electrical fields to remove submicron particles from oil. This advanced technology is especially beneficial in industries requiring ultra-clean oil, such as automotive and high-precision manufacturing. These machines enhance the performance and lifespan of machinery by ensuring the oil remains free of fine particulates. Their efficiency and reliability make them a valuable asset for maintaining high-performance equipment.

- Electrostatic oil purifiers effectively eliminate submicron particles using electrical fields.

- They are ideal for industries like automotive and high-precision manufacturing.

- These machines improve machinery performance and longevity, driving their widespread adoption.

Thermal Oil Purification Machines

Thermal oil purification machines use heat to remove contaminants like moisture and debris. By heating the oil, these machines enable the separation of water and other impurities, ensuring the oil remains clean and efficient. This method is particularly useful for maintaining lubrication efficiency and preventing corrosion in critical equipment. ZANYO’s thermal purification systems optimize operational efficiency while reducing maintenance costs.

| Benefit | Description |

|---|---|

| Moisture Control | Prevents corrosion and maintains lubrication efficiency. |

| Particle Removal | Reduces wear on turbine components by eliminating debris. |

| Increased Equipment Reliability | Clean oil extends the lifespan of critical equipment. |

| Reduced Maintenance Costs | Predictive maintenance minimizes unplanned downtime and lowers expenses. |

| Improved Operational Efficiency | Optimized processes lead to greater energy efficiency and a smaller environmental footprint. |

Coalescing Oil Filtration Machines

Coalescing oil filtration machines specialize in removing water from oil by combining small water droplets into larger ones, which are then separated from the oil. These machines are highly effective for applications where water contamination poses a significant risk, such as in hydraulic systems and turbines. Their ability to maintain oil purity ensures the smooth operation of machinery and reduces the risk of equipment failure.

| Filtration System Type | Contaminants Addressed | Applications |

|---|---|---|

| Coalescing Oil Filtration | Water | Hydraulic systems, turbines |

By understanding the types of oil filtration machines available, you can make informed decisions to enhance your machinery’s performance and longevity.

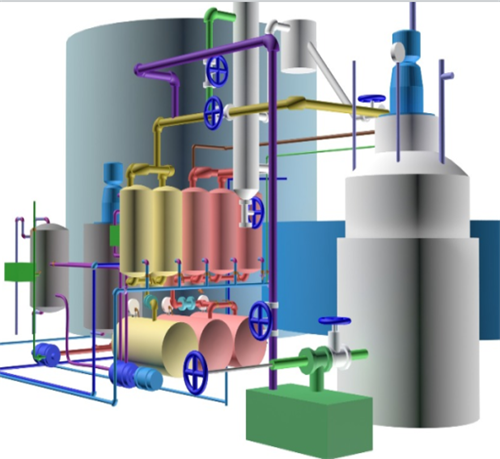

How Industrial Oil Filtration Systems Work

Filtration and Separation Processes

Industrial oil filtration systems rely on advanced processes to remove impurities and maintain oil quality. These systems use various methods to separate contaminants, ensuring your machinery operates efficiently.

- Mechanical filtration systems use physical barriers like coarse, fine, or high-efficiency filters to capture solid particles.

- Centrifugal filtration systems apply centrifugal force to separate impurities based on density, effectively removing particulate matter and free water.

- Vacuum filtration systems lower pressure to evaporate volatile contaminants, enabling the removal of water and gases from oil.

Each method targets specific impurities, ensuring the oil remains clean and suitable for industrial use. By understanding these processes, you can select the right system for your needs.

Removal of Water, Gas, and Solid Contaminants

Removing water, gas, and solid impurities is critical for maintaining oil performance. Industrial oil filtration systems achieve this through specialized techniques. Mechanical filtration captures solid particles, while vacuum filtration removes water and gases by reducing their boiling points. Portable systems offer flexibility, efficiently eliminating water and particulate matter on-site.

Monitoring water contamination is essential. Tools like BS&W bowls and sight glasses help detect water presence. Maintaining moisture levels between 50-300 parts per million ensures optimal equipment performance. Proper filter management, including selecting the right filters, minimizes contamination risks and extends oil life.

Advanced Technologies in Oil Filtration

Modern oil filtration systems incorporate innovative technologies to enhance efficiency and reliability. Intelligent manufacturing integrates automation and data analytics, enabling self-optimization and predictive maintenance. Enhanced processing efficiency allows systems to handle larger oil volumes while maintaining high purity levels. Improved automation control ensures precise adjustments, reducing human error and optimizing performance.

| Technological Advancement | Description | Benefits to Power Industry |

|---|---|---|

| Intelligent manufacturing | Integration of automation and data analytics for self-optimization and predictive maintenance. | Increases equipment reliability and reduces maintenance costs. |

| Enhanced processing efficiency | Ability to process larger volumes of oil rapidly while maintaining high purity levels. | Improves overall operational efficiency and reduces downtime. |

| Improved automation control | Advanced systems for precise adjustments to operating parameters, minimizing human error. | Enhances safety and optimizes performance under varying conditions. |

These advancements ensure your oil filtration system delivers superior performance, reducing downtime and operational costs.

Applications of Industrial Oil Purification Machines

Industrial oil purification machines serve a wide range of industries, ensuring machinery operates efficiently and reliably. Below are some key applications where these machines play a critical role.

Power Generation and Transformer Maintenance

In power generation, maintaining oil purity is essential for turbine and transformer performance. Regular oil filtration reduces friction between turbine components, enhancing lubricating properties and preventing wear. Clean oil minimizes unexpected breakdowns, cutting downtime and maintenance costs. ZANYO’s high-vacuum oil filtration machines, such as the ZYD-II, are ideal for transformer maintenance, ensuring dielectric properties remain intact.

- Prolongs the life of critical machinery parts.

- Reduces operational disruptions and maintenance expenses.

- Enhances the reliability of power generation systems.

Manufacturing and Heavy Machinery

In manufacturing, oil filtration machines improve equipment performance by maintaining oil purity. They reduce downtime and extend machinery lifespan, ensuring smooth operations. Electrostatic oil purifiers are particularly effective in removing submicron particles, making them suitable for industries requiring ultra-clean oil. ZYON’s advanced filtration systems cater to these needs, supporting high-precision manufacturing processes.

- Keeps machinery running efficiently.

- Reduces wear and tear on components.

- Supports automation in manufacturing processes.

Automotive and Transportation Industries

Automotive and transportation industries rely on high-quality lubricants to maintain vehicle performance. Oil filtration machines remove contaminants, ensuring lubricants remain effective. This reduces engine wear, improves fuel efficiency, and extends the life of vehicles. Portable oil filtration machines from ZANYO provide on-site maintenance solutions, making them invaluable for fleet management.

Marine and Offshore Applications

Marine and offshore environments demand robust oil filtration systems to handle harsh conditions. These machines remove water and debris from lubricants, preventing corrosion and ensuring engine reliability. ZANYO’s coalescing oil filtration machines excel in these settings, maintaining oil quality and reducing the risk of equipment failure.

- Prevents corrosion in marine engines.

- Ensures smooth operation in challenging environments.

- Reduces maintenance frequency and costs.

Food Processing and Pharmaceutical Industries

In food processing and pharmaceuticals, oil filtration ensures compliance with stringent quality standards. These industries require ultra-clean oil to avoid contamination. ZANYO’s filtration systems meet these demands, providing reliable solutions for maintaining oil purity and supporting safe production processes.

- Ensures compliance with industry regulations.

- Maintains product safety and quality.

- Reduces waste and operational costs.

Industrial oil purification machines, like those from ZANYO, offer versatile solutions across these applications. They enhance operational efficiency, reduce costs, and ensure machinery longevity.

Choosing the right industrial oil purification machine ensures your machinery operates efficiently. Each machine addresses specific needs, helping you maintain clean oil and reduce costs. ZANYO’s advanced systems enhance performance and extend equipment life. Evaluate your industry’s requirements carefully. Consider factors like oil type, contamination levels, and operational demands to select the best solution.

FAQ

What is the purpose of industrial oil purification machines?

Industrial oil purification machines remove contaminants like water, gas, and particles. They ensure oil quality, improve machinery performance, and reduce maintenance costs.

How does ZANYO’s vacuum oil purification machine work?

ZYON’s vacuum oil purification machine uses advanced vacuum technology to evaporate water and gases. It restores oil purity and enhances equipment reliability.

Can ZANYO’s machines handle on-site oil purification?

Yes, ZANYO offers portable oil filtration machines. These systems provide flexible, on-site solutions for maintaining oil purity in various industrial settings.