Key Takeaways

- Cleaning and reusing waste oil helps the environment by cutting pollution and saving resources.

- Companies can save cash and earn money by using cleaned oil instead of buying new, which is a smart financial move.

- People can help by keeping used oil safely and taking it to recycling places, promoting eco-friendly habits.

Challenges of waste lubricating oil disposal

1. Environmental risks of improper disposal

Improper disposal of waste lubricating oil poses significant environmental threats. When dumped into soil or water, the oil can contaminate ecosystems. It creates a barrier that prevents oxygen from reaching aquatic life, leading to suffocation of fish and other organisms. The oil also contains toxic substances like heavy metals, which can leach into groundwater. This contamination affects drinking water supplies and agricultural land. Furthermore, waste oil spills can harm wildlife by coating their fur or feathers, reducing their ability to regulate body temperature.

2. Health hazards from waste oil contamination

Exposure to waste lubricating oil can harm human health. The oil often contains harmful chemicals, including polycyclic aromatic hydrocarbons (PAHs) and heavy metals. These substances can cause skin irritation, respiratory issues, and even long-term illnesses like cancer. Workers handling waste oil without proper safety measures face the highest risks. Communities near contaminated sites may also experience health problems due to polluted air, water, or soil. Protecting public health requires proper handling and disposal of waste oil.

3. Regulatory requirements and compliance challenges

Governments worldwide enforce strict regulations for waste lubricating oil disposal. These laws aim to prevent environmental damage and protect public health. However, compliance can be challenging for businesses. They must invest in proper storage, transportation, and treatment facilities. Small companies may struggle with the costs of meeting these requirements. Additionally, lack of awareness or enforcement in some regions leads to illegal dumping. Addressing these challenges requires collaboration between industries, governments, and communities.

Waste lubricating oil purification and recovery process

1. Collection and transportation of waste oil

- Collect waste oil from industries, automotive centers, and households.

- Use specialized containers for safe storage and prevent leaks.

- Licensed transporters move oil to treatment facilities with proper documentation for compliance.

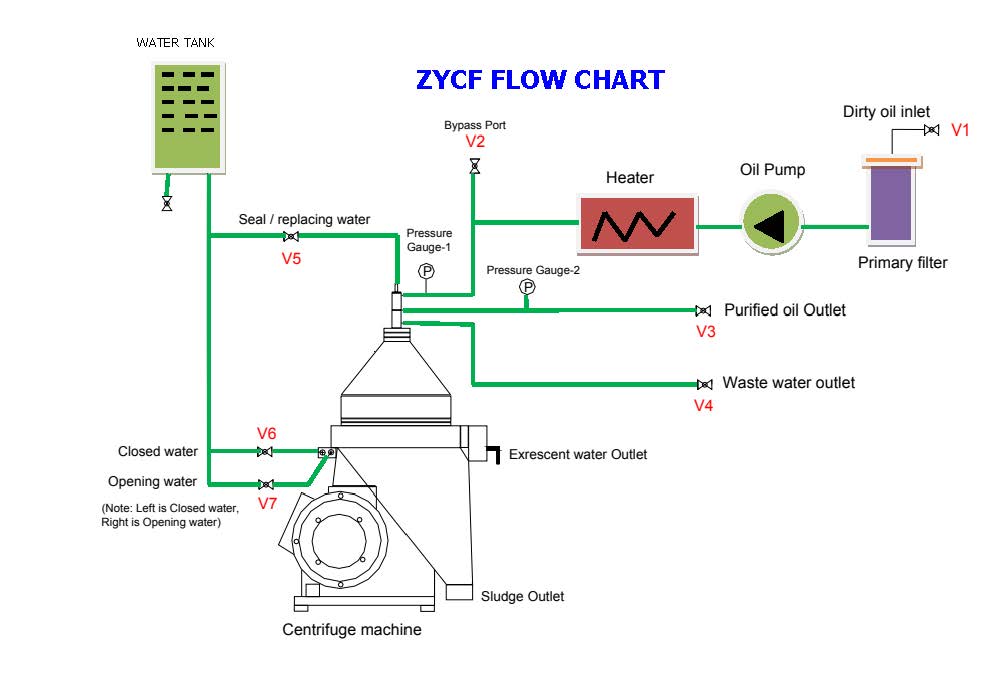

2. Pre-treatment methods for waste oil

- Pre-treatment removes large debris, water, and impurities.

- Settling tanks separate heavy and light contaminants.

- Centrifugation separates water and solids, ensuring oil is ready for advanced purification.

3. Purification techniques

- Filtration removes small particles.

- Distillation separates components by boiling points.

- Chemical treatments neutralize acids and remove harmful substances.

- Combining methods enhances purification effectiveness.

4. Recovery and re-refining processes

- Recover valuable components and re-refine oil to its original state.

- Use advanced technologies and add additives for improved performance.

- Re-refined oil often matches or exceeds virgin oil quality, reducing new oil demand.

Benefits of waste lubricating oil purification and recovery

1. Environmental benefits: pollution reduction and resource conservation

Purifying and recovering waste lubricating oil significantly reduces environmental pollution. Reusing oil prevents improper disposal, which often contaminates soil and water. This process also minimizes the extraction of crude oil, conserving natural resources. By reducing the need for new oil production, industries lower their carbon footprint. Cleaner ecosystems and preserved resources benefit both wildlife and human communities.

2. Economic benefits: cost savings and revenue generation

Re-refining waste lubricating oil offers substantial economic advantages. Businesses save money by reusing oil instead of purchasing new supplies. The recovery process also creates opportunities for revenue generation. Companies can sell re-refined oil or byproducts to other industries. Additionally, governments often provide incentives for sustainable practices, further reducing costs. These financial benefits make oil purification an attractive option for businesses of all sizes.

3. Contribution to sustainable and circular economies

Waste lubricating oil purification supports the transition to a circular economy. This approach focuses on reusing materials to reduce waste and extend product lifecycles. Re-refined oil exemplifies this principle by transforming waste into a valuable resource. Industries that adopt this practice contribute to sustainability by reducing reliance on finite resources. A circular economy promotes long-term environmental and economic stability, benefiting future generations.

Waste lubricating oil purification and recovery play a vital role in protecting the environment and supporting economic sustainability.

By reducing pollution, conserving resources, and lowering costs, this process offers numerous advantages.

Adopting these practices helps industries and individuals contribute to a cleaner planet. Exploring these methods ensures a sustainable future for generations to come.

FAQ

What is the difference between purification and re-refining of waste oil?

Purification removes contaminants to improve oil quality. Re-refining restores used oil to its original state, making it comparable to new oil in performance and reliability.

How can individuals contribute to waste oil recovery?

Individuals can store used oil in sealed containers and deliver it to recycling centers. Proper disposal prevents environmental harm and supports sustainable waste management practices.

Is re-refined oil as effective as virgin oil?

Yes, re-refined oil often matches or exceeds virgin oil quality. Advanced technologies ensure it meets industry standards, making it suitable for various applications.