Performance and Usages

ZYD-I Double Stages Vacuum Transformer Oil Treatment Machine specifically designed for purifying electrical insulating oil (transformer oil, switch oil, mutual oil, cable oil, capacitor oil) in the oil-filled electrical equipment. ZYD-I Double stages vacuum transformer oil treatment machine is particularly suitable for treating high-grade transformer oil, super-voltage transformer oil and new transformer oil. It is widely used in factory workshops, power transmission, transformer stations and generation stations.

ZYD-I can remove particles, dewater, degas from the old and new insulating oil more effectively; It is especially suitable for the 110KV-500KV above large-scale transformer stations, ZYD-I is an upgrade generation of ZYD.

ZYD-I adopts special double horizontal evaporation system, double rows spray nozzle, evaporation area enlarged.

Working Principle

Under vacuum and negative pressure state, the water can be vaporized in low temperature, the higher vacuum state; the lower of water boiling point, the water is vaporized faster. Even under same temperature, water can be moved faster under vacuum state. Oil goes into heater after purified by primary filter, Oil temperature goes up when heated. Then oil goes in to vacuum separator to become oil film by the film sprayer. In vacuum separator, water becomes vapor, and discharged by vacuum.

Technical Features

- ZYD-II double stages vacuum insulation oil treatment machine is compacted process design, it is convenient to move.

- Adopting many innovative designs from oil purifier industrial at home and abroad, it is at the leading level in oil treatment technology and equipment performance, with characteristics of high working vacuum, high oil purifying efficiency and high precision.

- Control System: Optimized design of control interlock protection device, overpressure alarm and protection, phase sequence protection, to ensure whole machine working stably for a long time. Automatic pressure alarm system, automatic overload protection system, automatic constant temperature system, automatic bubble elimination system, automatic protection of blowout prevention and other advanced technologies, to ensure the safe operation of untended operation.

- Degassing And Dehydration System: Adopting advanced atomizing system, three-dimensional separation tower and flash evaporation technology, it can quickly remove moisture and gas from the oil by forming parabolic in the special designed vacuum tank.

- Oil Filtration System: Adopt high quality filter element, multi-stage precise filtration, and level-by-level encryption technology, which can remove fine impurities and absorb large amount of pollution. Primary filter can be cleaned and used repeatedly without secondary pollution.

- Heating System: by using of high quality heating elements, excellent corrosion resistance, thermal stability, viscosity resistance, insulation, chemical resistance and wear resistance. The safe and reliable carbon fiber heating system with the functions of quickly heating, heating uniform, etc..

- Oil Transferring System: adopt to choose different type of oil pump according to the oil quality and oil viscosity. Special material and special performance curve ensure that oil flowing will never cause gap discharge to bring acetylene, oil treatment process and equipment performance is in the leading position.

- Transformer Oil Recycling System(optioinal): It can quickly remove carbon deposition from transformer oil which caused by arc, to make the inferior oil quality reach new oil standard.

- Optional Configuration: PLC control, touch screen, moisture sensor, BDV Oil tester, enclosed doors, mobile trailer, lights, tool box, special frame designing, etc.

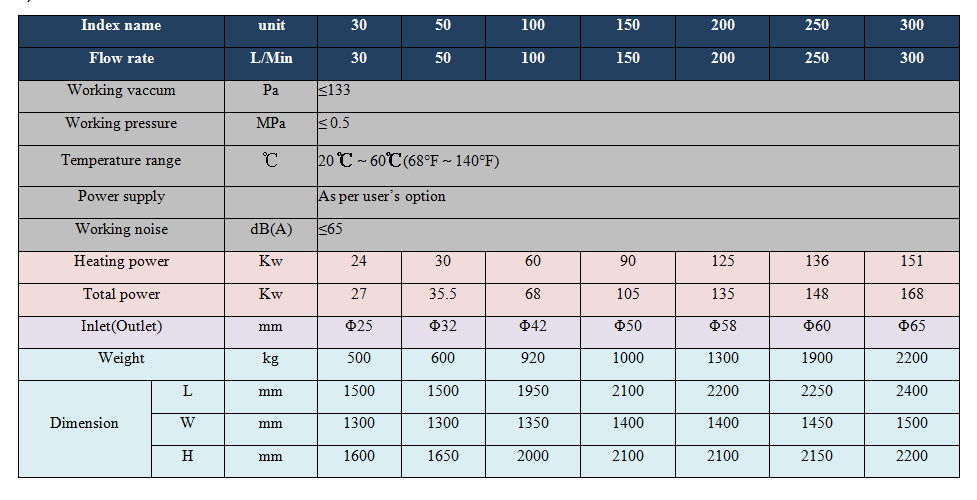

Technical Parameters