A lube oil purification machine helps you maintain equipment efficiency while cutting costs and protecting the environment. Cleaner oil can extend machine lifespan by up to 35%. Additionally, doubling oil drain intervals reduces greenhouse gas emissions by over one million metric tons annually, making it a sustainable choice for industrial operations.

Key Takeaways

- A lube oil purifier helps machines last longer by 35%. It removes dirt and harmful particles.

- Clean oil lowers costs a lot. You can save thousands on repairs and oil replacements.

- Using a lube oil purifier is eco-friendly. It cuts waste and lowers harmful gas emissions.

Benefits of a Lube Oil Purification Machine

Prolonging Equipment Lifespan

A lube oil purification machine helps you protect your equipment by removing harmful contaminants. Clean oil reduces wear and tear on engine parts, preventing costly breakdowns. For example, purified oil minimizes friction, which enhances engine performance and extends the life of critical components. This process ensures your machinery operates efficiently for longer periods, reducing the need for frequent repairs or replacements.

| Benefit | Description |

|---|---|

| Enhanced Equipment Life | Clean lube oil prevents contaminants from damaging engine parts, reducing breakdowns and costs. |

| Improved Efficiency | Purified oil reduces friction, enhancing engine performance and productivity. |

Reducing Operational Costs

Using a lube oil purification machine can significantly lower your operational expenses. Reusing purified oil reduces the frequency of oil changes, saving you money on maintenance. For instance, industries that adopted purification systems reported substantial savings. One service cost only $0.80 per gallon, resulting in $17,300 saved on oil costs. These savings add up over time, making purification systems a cost-effective solution for your business.

Supporting Environmental Sustainability

Purifying and reusing oil benefits the environment by reducing waste. Instead of disposing of used oil, you can clean and reuse it, minimizing your environmental footprint. This process also reduces greenhouse gas emissions associated with oil production and disposal. By adopting a lube oil purification machine, you contribute to a more sustainable future while maintaining efficient operations.

How a Lube Oil Purification Machine Works

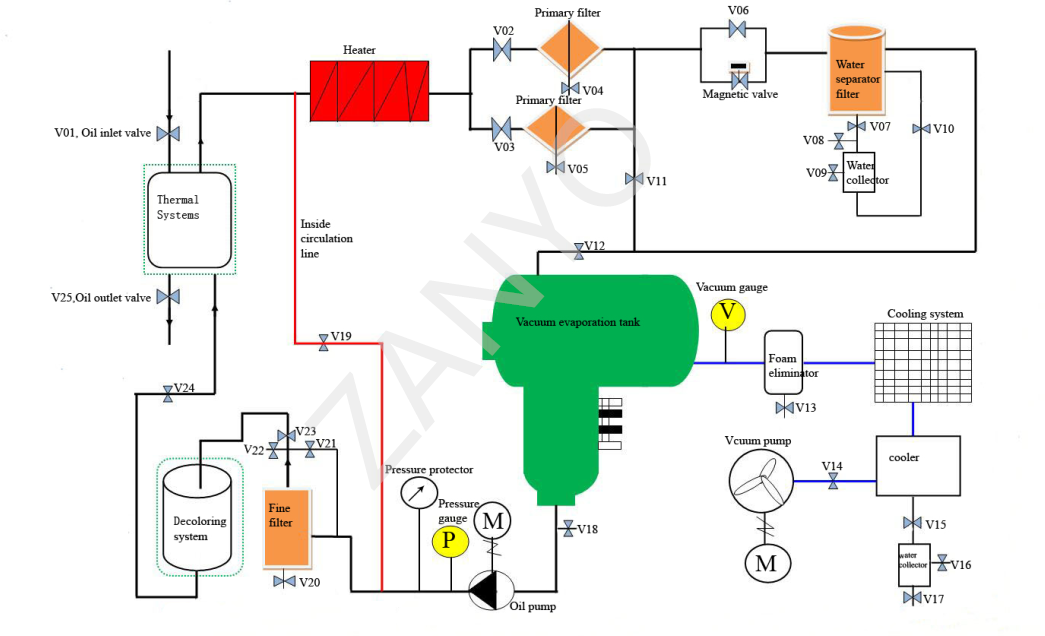

Key Processes (Filtration, Dehydration, Degassing)

A lube oil purification machine uses advanced processes to clean and restore oil to its optimal condition. These processes include filtration, dehydration, and degassing.

- Filtration: This step removes solid particles like dirt and metal shavings that accumulate in the oil. These contaminants can cause wear on engine components, leading to costly repairs. By eliminating these particles, filtration ensures smooth operation and extends equipment life.

- Dehydration: Water in oil can lead to corrosion and reduced lubrication efficiency. Dehydration separates water from the oil, preventing damage to machinery and maintaining oil performance.

- Degassing: Dissolved gases in oil can affect its lubricating properties. Degassing removes these gases, ensuring the oil remains effective under high-pressure conditions.

These processes often rely on centrifugal and vacuum technologies. Centrifugal force separates impurities through high-speed rotation, while vacuum systems create low-pressure environments to extract moisture and gases. Together, these methods enhance oil cleanliness and performance.

Types of Machines and Their Applications

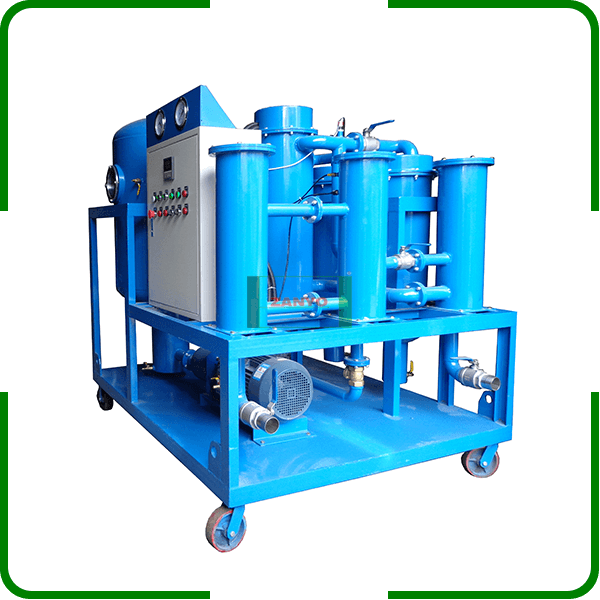

Lube oil purification machines come in various types, each designed for specific applications.

- Centrifugal Machines: These machines use centrifugal force to remove contaminants. They are ideal for industries requiring high-speed purification, such as power plants and marine operations.

- Vacuum Purifiers: These systems excel at removing water and gases. They are commonly used in industries where oil must meet strict quality standards, like aviation and manufacturing.

- Portable Units: Compact and mobile, these machines are perfect for on-site purification in remote locations or smaller facilities.

Each type of machine offers unique benefits, allowing you to choose one that suits your operational needs. By selecting the right lube oil purification machine, you can improve efficiency, reduce costs, and protect your equipment.

Choosing the Right Lube Oil Purification Machine

Factors to Consider (Capacity, Efficiency, Cost)

Selecting the right lube oil purification machine involves evaluating several critical factors to match your operational needs.

- Transformer Capacity and Voltage Level: The size of your transformer determines the purifier’s required flow rate. Larger transformers need machines with higher processing capabilities.

- Flow Rate: This factor dictates how quickly the machine can purify oil. A higher flow rate is ideal for large-scale operations with tight schedules.

- Vacuum Level: Machines with higher vacuum levels remove contaminants more effectively, ensuring optimal oil quality.

- Filtration Rating: The filtration rating indicates the smallest particle size the machine can capture. A finer rating ensures better oil cleanliness.

- Oil Type Compatibility: Ensure the machine supports the specific type of oil you use to achieve efficient purification.

- Mobility: Portable machines are suitable for on-site applications, while stationary models work best for centralized operations.

Considering these factors helps you choose a machine that balances performance, cost, and efficiency.

Maintenance and Longevity Tips

Proper maintenance ensures your lube oil purification machine operates efficiently for years. Follow these tips to maximize its lifespan:

- Regular Cleaning: Clean the filtration system and other components frequently to prevent clogging and maintain performance.

- Monitor Oil Quality: Test the purified oil periodically to ensure the machine is functioning correctly.

- Replace Worn Parts: Inspect and replace worn-out parts like filters and seals to avoid unexpected breakdowns.

- Follow Manufacturer Guidelines: Adhere to the maintenance schedule and recommendations provided by the manufacturer, such as ZANYO, to keep the machine in top condition.

By implementing these practices, you can reduce downtime, lower repair costs, and extend the machine’s service life.

A lube oil purification machine offers undeniable benefits for your business and the environment. It optimizes equipment performance, reduces costs, and supports sustainability.

- Investing $1,000 in proper lubrication practices can save $40,000, delivering a 3,900% ROI.

- You also save on oil usage and disposal costs while reducing oily waste.

By choosing the right machine, like those from ZANYO, you achieve long-term cost savings and meet environmental goals.

FAQ

What industries benefit the most from lube oil purification machines?

Industries like manufacturing, power generation, marine, and aviation benefit greatly. These machines improve equipment efficiency, reduce costs, and support sustainability in high-demand operations.

How often should you maintain a lube oil purification machine?

Perform maintenance regularly, such as cleaning filters and inspecting parts. Follow the manufacturer’s guidelines, like those from ZANYO, to ensure optimal performance and longevity.

Can a lube oil purification machine handle all types of oil?

Not all machines are compatible with every oil type. Check the machine’s specifications to ensure it supports the oil used in your operations.