Reliable Lube Oil Purifiers China Manufacturer & Supplier

Ensure your machinery operates at peak efficiency with the Zanyo’s lube oil purifiers. Designed for industrial applications, this advanced oil purifying machine helps extend the life of your lubricants, reduce maintenance costs, and improve overall equipment performance.

As an OEM manufacturer and supplier, Zanyo offers customized solutions tailored to your specific needs, with competitive pricing to ensure affordability.We deliver high-performance lube oil purification systems that meet rigorous standards for reliability and effectiveness.

Lube Oil Purifier Series From ZANYO

Zanyo offers customizable options to meet the unique needs of different users, including the integration of PLC control systems and remote operation capabilities. With PLC control, users can program and set specific operational parameters (such as filtration speed, duration, and more), enhancing the accuracy and efficiency of the equipment while reducing the need for manual intervention.

Additionally, we can equip the system with remote operation features, allowing users to monitor and control the equipment from any location, eliminating the need for on-site management. This flexibility and convenience make our oil purification equipment more intelligent and adaptable to various industrial applications, ensuring optimal performance and ease of use.

Lube Oil Purification Systems

A lube oil purification system is designed to remove impurities from lubricating oil used in engines and industrial equipment. Over time, oil accumulates dirt, water, carbon particles, and other harmful substances that can affect machinery performance. These systems help maintain oil quality by filtering out contaminants, ensuring smooth operation.

Lube Oil Purifier Function

A oil purifier machine performs essential functions to ensure lubricating oil remains clean and effective for prolonged use. It is designed to remove various contaminants from used oil, ensuring optimal machinery performance and reducing the need for frequent oil changes.

Key Functions of a Lube Oil Purifier:

- Particle Filtration – Removes solid particles such as small metal pieces, and carbon residue that accumulate in the oil during operation, preventing wear on engine components.

- Gas Separation – Extracts dissolved gases, like carbon dioxide, from the oil to prevent foaming and maintain the oil’s lubricating properties.

- Water Separation – Separates water that may mix with the oil due to condensation or leakage, preventing corrosion and deterioration of the oil’s performance.

- Sludge Removal – Eliminates sludge buildup, ensuring the oil remains clean and effective for lubrication.

Lube Oil Purifier Working Principle

In lube oil purification systems, both centrifugal and vacuum technology play a critical role in improving oil cleanliness and flow. Each system has its unique working principle.

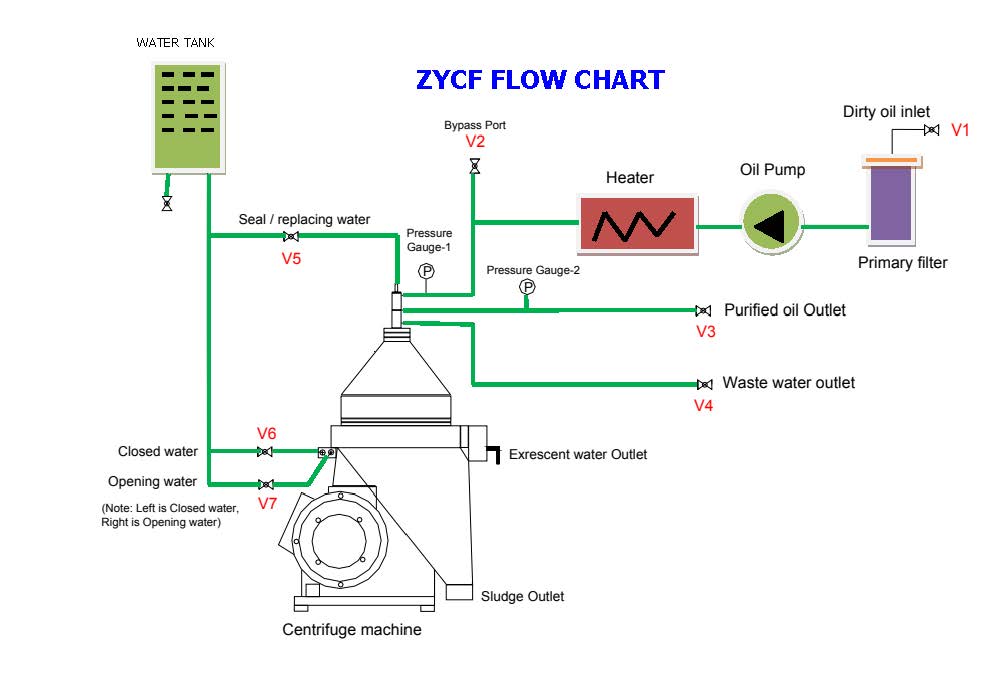

- Centrifugal force works by generating high-speed rotation, effectively separating impurities from the oil. In a centrifugal oil filter, oil is pumped into a centrifugal bowl. Under high-speed rotation, larger particles and contaminants, due to their greater mass, are pushed toward the outer walls of the bowl. Through this process, clean oil flows out, while contaminants settle on the bowl wall, where they are periodically removed.

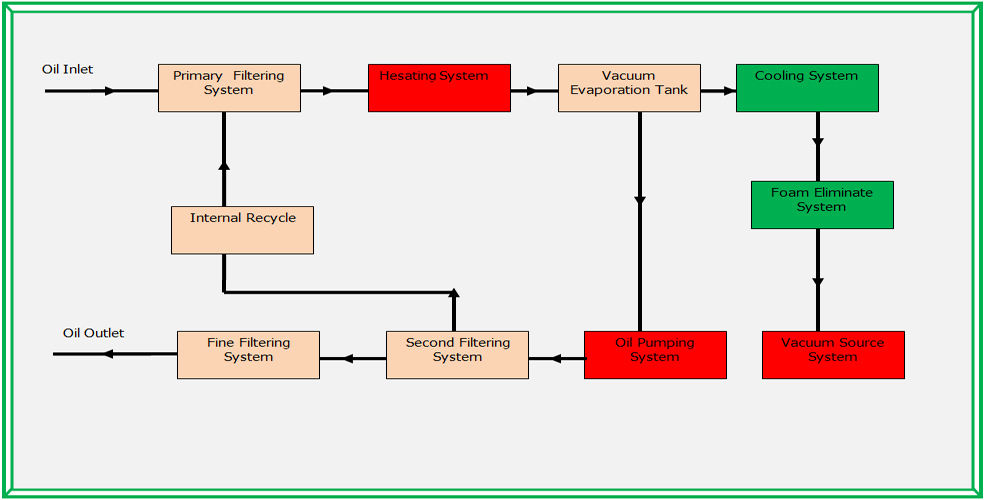

- The vacuum purification system operates by creating a low-pressure environment to remove dissolved gases, moisture, and light volatile substances from lubricating oil. This process relies on the reduction in boiling points of these impurities under vacuum conditions, causing them to evaporate and separate from the oil. The clean oil then passes through a filter to remove solid contaminants. This purification prevents oxidation, reduces foam formation, and maintains the oil’s viscosity and lubrication efficiency.