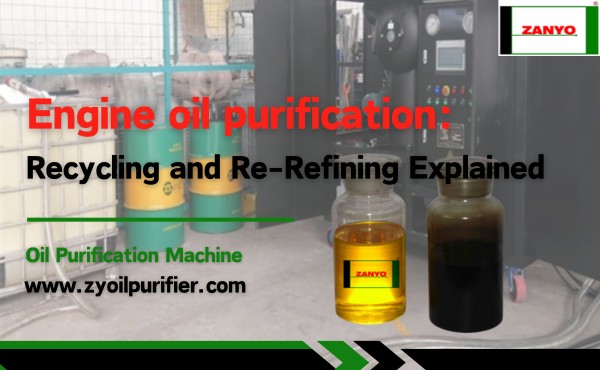

Engine oil purification plays a crucial role in managing waste and conserving natural resources. Used oil, when left untreated, harms the environment. Recycling transforms this waste into a reusable resource, reducing pollution. Engine oil purification ensures that contaminants are removed, making the oil suitable for reuse. This process supports sustainability and resource conservation.

Key Takeaways

- Recycling old engine oil helps the environment. It stops soil and water pollution. Safe disposal keeps nature clean.

- Cleaning and reusing old oil saves resources. It cuts down the need for making new oil. This method uses less energy and helps the planet.

- Purifying oil creates jobs and boosts the economy. It supports businesses and protects Earth by reusing materials.

Benefits of Engine Oil Purification

Environmental benefits: Reducing pollution and conserving resources

Recycling used oil significantly reduces environmental pollution. Improper disposal of used oil can contaminate soil and water, harming ecosystems. Recycling prevents this by ensuring proper collection and purification. Re-refining transforms used oil into a reusable resource, reducing the need for crude oil extraction. This process conserves natural resources and minimizes the carbon footprint associated with new oil production. By adopting recycling practices, industries contribute to cleaner air, water, and land.

Economic advantages: Cost savings and creating a circular economy

Recycling and re-refining used oil offer substantial economic benefits. The collection and purification of used oil reduce the demand for new oil, lowering production costs. Re-refining also creates jobs in industries focused on oil recycling and purification. These industries support a circular economy by turning waste into valuable resources. Businesses save money by reusing oil instead of purchasing new supplies. This approach benefits both companies and consumers by promoting cost efficiency.

Sustainability: Supporting long-term resource management

Recycling used oil supports sustainable resource management. Crude oil is a finite resource, and re-refining extends its usability. Proper collection and recycling practices ensure that used oil does not go to waste. This approach aligns with global efforts to reduce reliance on non-renewable resources. Re-refining also reduces greenhouse gas emissions, contributing to climate change mitigation. By prioritizing recycling, industries and individuals help secure resources for future generations.

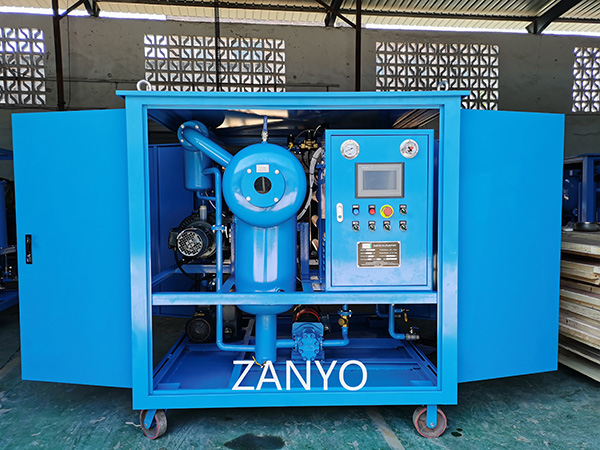

Types of Engine oil purification machine

Engine oil purification machines play a critical role in recycling and re-refining processes. These machines remove contaminants from motor oil, making it reusable and environmentally friendly. Two common types of purification machines are centrifugal purifiers and vacuum purifiers.

Centrifugal Oil Filtration

A centrifugal oil purifier uses centrifugal force to separate impurities from motor oil. The machine spins the oil at high speeds, causing heavier particles like dirt and sludge to move outward. Lighter components, such as clean oil, remain closer to the center. This method effectively removes solid contaminants and water from used oil.

Centrifugal oil purifiers are efficient and widely used in industries. They handle large volumes of oil and require minimal maintenance. Their ability to separate impurities without using chemicals makes them an eco-friendly option. This technology ensures that motor oil is purified quickly and effectively, reducing waste and supporting sustainability.

Vacuum Dehydration Purification

A vacuum oil purifier removes water, gases, and light hydrocarbons from motor oil by creating a vacuum environment. The machine heats the oil under reduced pressure, causing unwanted substances to evaporate. The purified oil is then collected for reuse.

This method is particularly effective for removing moisture, which can degrade motor oil quality. Vacuum purifiers are commonly used in industries where high-quality oil is essential. They extend the lifespan of motor oil and improve its performance. By using this technology, industries can reduce their reliance on new oil production and minimize environmental impact.

The Recycling and Re-Refining Process

The re-refining process transforms used oil into a high-quality product that can be reused. This process involves several steps, each designed to remove impurities and restore the oil’s properties.

Dewatering: Removing water and impurities

Dewatering is the first step in the re-refining process. Used oil often contains water, which can degrade its quality. In this step, the oil is heated to separate water and light impurities. The water evaporates, leaving behind the oil for further treatment. This step ensures that the remaining oil is free from moisture, which is essential for maintaining its performance.

Filtering: Eliminating solid contaminants

Filtering removes solid particles such as dirt, metal fragments, and sludge from the used oil. These contaminants can damage machinery if left untreated. The oil passes through fine filters that trap these particles, leaving it cleaner and ready for the next stage. This step is crucial for ensuring the oil’s usability and protecting equipment.

Vacuum Distillation: Separating oil into usable fractions

Vacuum distillation separates the oil into different fractions based on their boiling points. The process occurs under reduced pressure, which lowers the boiling point of the oil. This method prevents thermal degradation and ensures the recovery of valuable components. The separated fractions can then be refined further or used directly in various applications.

Hydrotreatment: Enhancing oil quality and removing remaining chemicals

Hydrotreatment is the final step in the re-refining process. It uses hydrogen gas to remove any remaining impurities, such as sulfur and nitrogen compounds. This step improves the oil’s color, odor, and overall quality. The result is a high-grade product that meets industry standards and can replace new oil in many applications.

Engine oil purification plays a crucial role in environmental protection, economic savings, and sustainable resource management. By removing contaminants and reusing motor oil, industries reduce pollution, conserve natural resources, and minimize reliance on new oil production.

Centrifugal and vacuum oil purifiers are effective technologies that support these processes, ensuring high-quality oil for future use. The re-refining process, from dewatering to hydrotreatment, restores oil properties, making it suitable for reuse. By embracing these methods, businesses contribute to a circular economy, reduce waste, and promote a cleaner, more sustainable future.

BUY ENGINE OIL PURIFIER MACHINE HERE

FAQs

What happens if used engine oil is not recycled?

Improper disposal of used oil contaminates soil and water. It harms ecosystems and poses risks to human health. Recycling prevents pollution and protects the environment.

Can re-refined oil match the quality of new oil?

Yes, re-refined oil meets industry standards. Advanced purification processes restore its quality, making it comparable to new oil in performance and reliability.

How much oil can be recovered through recycling?

Recycling one gallon of used oil produces approximately 0.7 gallons of reusable oil. This process conserves resources and reduces the need for crude oil extraction.