Centrifugal Oil Filtration Machine From China Manufacturer

ZANYO is a trusted manufacturer and supplier from China, offering high-quality centrifugal oil filtration machines. We provide custom solutions to help businesses improve oil life, reduce downtime, and cut maintenance costs. Our machines are built for reliability and efficiency, catering to a range of industries. At ZANYO, we focus on delivering products that meet your specific needs with excellent service and support.

ZANyo Centrifugal Oil Filtration systems

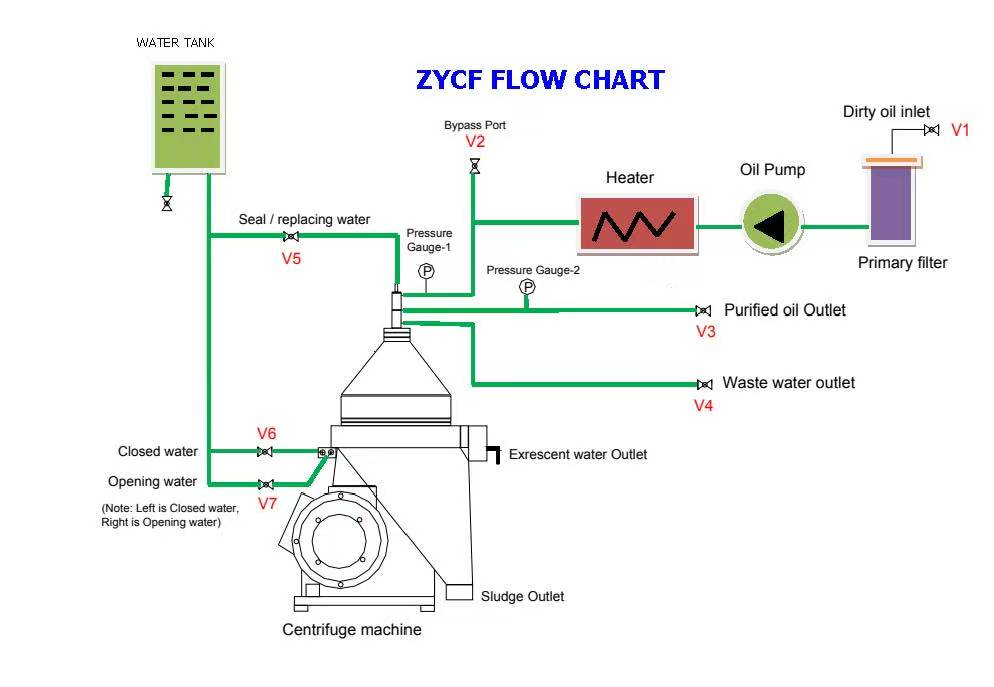

ZANYO’s centrifugal oil filtration machine is designed to efficiently purify and maintain oil quality by utilizing several key components that work together to ensure optimal performance. These key components include:

- Water Tank: The water tank plays a critical role in temperature regulation. It helps manage the heat generated during the centrifugal separation process, preventing overheating of the oil.

- Pressure Gauge: The pressure gauge monitors the system’s pressure at different points in the filtration process. It ensures that the oil flows at the correct pressure. Gauge helps detect potential issues like blockages or system malfunctions, ensuring the system operates within safe and optimal conditions.

- Heater: Heating the oil improves its fluidity, making it easier for the centrifugal force to separate contaminants. This enhances the efficiency of the filtration process and reduces wear on the system’s components by preventing the oil from becoming too thick or sluggish.

- Oil Pump: The oil pump is responsible for circulating the oil through the system. It maintains the required flow rate and pressure, ensuring the system operates at maximum efficiency.

- Primer Filter: The primer filter acts as the first line of defense, capturing larger particles and contaminants before the oil enters the centrifugal separator.

- Motor: Motor provides the rotational power needed to drive the separator’s rotor at high speeds, generating the centrifugal force required to separate contaminants from the oil.

ZANYO Centrifugal Oil Filtration Systems

Why Choose ZANYO?

Centrifugal Oil Filter Working Principle

Centrifugal oil filtration is a highly effective method used to separate solid contaminants from oil in industrial machinery. This process relies on the principle of centrifugal force, which is generated by spinning the oil at high speeds. The difference in density between the oil and the contaminants plays a crucial role in the separation.

As the machine spins rapidly, centrifugal force causes the heavier solid particles to move outward towards the filter bowl’s wall. The lighter oil, being less dense, is pushed toward the center of the bowl. Over time, the solid contaminants accumulate and form a sludge cake on the outer edge, while the purified oil is collected at the center.

Benefits of Centrifugal Oil Filtration

Centrifugal oil filtration machines remove dirt and harmful particles from oil. It uses centrifugal force to clean the oil. This method is common in industries to keep oils working well. The main goal is to make machines last longer. Clean oil helps parts work smoothly and reduces damage. It also keeps engines and systems running efficiently by stopping harmful buildup. This process is very important for industries needing lubrication systems.

High Separation Efficiency

Centrifugal oil filtration uses centrifugal force to separate particles based on density. It removes even very small particles quickly and effectively. This method offers a higher separation efficiency compared to traditional filtration systems.

Faster Processing Time

Due to the powerful centrifugal force, centrifugal filtration processes oil much faster. It can handle large volumes of oil quickly, significantly reducing processing time when compared to vacuum filtration, which tends to be slower.

Lower Maintenance Costs

Centrifugal filters often require less frequent replacement of filter media. This reduces the overall cost of maintenance and replacement parts, saving you money in the long run.

Applications of Centrifugal Oil Filtration Systems

- Industrial and Manufacturing Equipment: Centrifugal oil filtration machine removes harmful particles from lubricating oil, ensuring machines run efficiently and reducing repairs.

- Power Generation and Energy: Centrifugal oil filters protect turbines and generators by keeping lubricating oil clean, reducing friction, and extending oil life.

- Marine and Aviation: For ships and aircraft, centrifugal filters remove contaminants from lubricating oil, ensuring engine safety and reliability.