Waste oil purification is a crucial process for environmental, economic and operational reasons. By refining waste oil, businesses can extend the life of their oil, reduce environmental impact, and cut costs. This practice not only helps in conserving natural resources but also enhances operational efficiency. In this article, we’ll explore the importance of waste oil purification and the benefits it offers to industries and the environment.

Environmental Benefits of Waste Oil Purification

Reducing Pollution

Waste oil purification significantly reduces pollution by removing harmful contaminants from used oil. When improperly disposed of, used oil can seep into soil and water, causing severe environmental damage. Purification prevents this by enabling the safe reuse of oil.

Advanced oil purification systems filter out impurities, ensuring cleaner oil for industrial applications. This process minimizes the release of toxic substances into the environment, protecting ecosystems and public health. By adopting waste oil re-refining practices, industries contribute to reducing the overall environmental impact of oil usage.

Conserving Natural Resources

Oil purification plays a crucial role in conserving natural resources. Crude oil extraction and refining require significant energy and raw materials. Re-refining used oil through effective purification methods reduces the demand for virgin oil production.

This approach supports sustainability by extending the lifecycle of oil products. Industrial oil purification ensures that high-quality oil is available for reuse, decreasing the need for new resources. Waste oil recycling also helps preserve finite natural reserves, promoting a more sustainable future.

Supporting Eco-Friendly Practices

Purification encourages eco-friendly practices by aligning with environmental sustainability goals. Businesses that invest in oil purification systems demonstrate a commitment to reducing their environmental footprint. These systems enhance oil quality, making it suitable for reuse in various applications.

Waste oil re-refining and recycling initiatives foster a circular economy, where resources are reused rather than discarded. Such practices not only benefit the environment but also improve a company’s reputation as an environmentally responsible entity.

Economic Advantages of Oil Purification

Cost Savings from Reuse

Oil purification offers significant cost savings by enabling the reuse of used oil. Instead of purchasing new oil, businesses can rely on purified oil that meets high-quality standards. This reduces the need for frequent oil replacement, cutting operational expenses.

Waste oil re-refining ensures that contaminants are removed, allowing the oil to perform efficiently in machinery. By investing in purification systems, companies can lower their dependency on virgin oil, which often comes with higher costs. These savings contribute to better financial management and long-term sustainability.

Reduced Disposal Costs

Proper oil purification minimizes the need for expensive disposal methods. Disposing of used oil often involves strict environmental regulations, which can lead to high costs for businesses. Purification reduces the volume of waste oil requiring disposal by converting it into reusable oil.

This not only saves money but also decreases the environmental impact of oil waste. Waste oil re-refining further supports this by ensuring that less oil ends up in landfills or incinerators. Companies benefit from reduced disposal fees while aligning with eco-friendly practices.

Revenue Opportunities

Oil purification can create new revenue streams for businesses. Purified oil can be sold to other industries that require high-quality oil for their operations. Waste oil re-refining produces oil that meets industry standards, making it a valuable commodity.

Companies with advanced purification systems can also offer purification services to other businesses, generating additional income. These opportunities not only enhance profitability but also promote recycling and sustainability. By turning waste oil into a marketable product, businesses contribute to reducing environmental pollution and conserving resources.

Operational Efficiency Through Purification

Improved Machinery Performance

Oil purification enhances machinery performance by ensuring the oil used in equipment is free from contaminants. Impurities in oil can disrupt the smooth operation of machinery, leading to inefficiencies and potential breakdowns. Purified oil maintains consistent viscosity and thermal stability, which are essential for optimal performance.

Waste oil re-refining processes remove harmful particles, allowing machinery to operate at peak efficiency. Industries that adopt oil purification systems experience fewer interruptions in their operations, resulting in increased productivity. Cleaner oil also reduces the risk of overheating, ensuring machinery functions reliably under demanding conditions.

Reduced Wear and Tear

Purification plays a critical role in minimizing wear and tear on industrial equipment. Contaminants in used oil can cause abrasive damage to machinery components, leading to premature failure. Oil filtration systems effectively eliminate these particles, protecting sensitive parts from unnecessary strain.

Re-refining used oil ensures that it meets high-quality standards, reducing friction and extending the life of mechanical components. By investing in waste oil purification, businesses can lower maintenance costs and avoid frequent repairs. This proactive approach not only improves equipment reliability but also reduces the environmental impact of frequent part replacements.

Extended Equipment Lifespan

Oil purification significantly extends the lifespan of machinery by maintaining the quality of the oil used. Regular purification prevents the accumulation of sludge and deposits that can degrade equipment over time. Waste oil recycling and re-refining processes ensure that oil remains clean and efficient, reducing the likelihood of long-term damage.

Businesses that prioritize purification benefit from reduced capital expenditures on new equipment. Sustainable practices, such as waste oil purification, contribute to the longevity of machinery while supporting environmental goals. This approach aligns with the principles of sustainability by promoting resource conservation and reducing pollution.

Conclusion

Waste oil purification offers significant environmental and economic benefits. It reduces pollution by eliminating harmful contaminants, conserves natural resources by reducing the demand for virgin oil, and supports eco-friendly practices that align with sustainability goals. Economically, it provides cost savings through oil reuse, reduces disposal fees, and creates new revenue opportunities.

Furthermore, it enhances operational efficiency by improving machinery performance, reducing wear and tear, and extending equipment lifespan. Adopting oil purification systems not only helps businesses lower costs and improve sustainability but also contributes to a cleaner, more efficient industrial future.

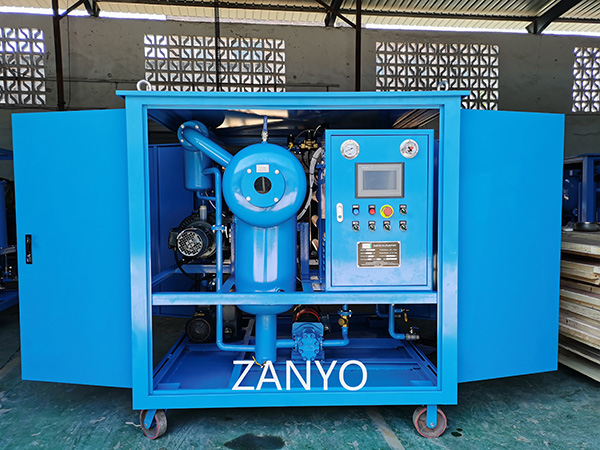

Partner With ZANYO for High Performance Oil Purification Machines

Ready to enhance your operations with high-performance oil purification? Partner with ZANYO today for advanced machines that boost efficiency, reduce costs, and support sustainability. Contact us now to learn how our solutions can help you optimize your oil usage and extend your equipment lifespan. Let’s take your business to the next level—together!