What is a Hydraulic oil purification machine?

A Hydraulic oil purification machine is used to clean hydraulic or lubricating oil with a high degree of purity. It can remove impurities such as dust, water, acid, alkali, and oxides from the oil to decontaminate, degreasing, and dehydration.

The oil after treatment by the machine can extend the service life of machinery and equipment, reduce maintenance costs, and create greater economic benefits for users.

How to operate a hydraulic oil purification machine?

The hydraulic oil purification machine is easy to operate. Just follow these simple steps:

1. Connect the power supply and turn on the machine.

2. Connect the inlet and outlet hoses to the machine.

3. Add oil to the tank and start the pump.

4. The machine will start purifying the oil automatically.

5. When the process is finished, turn off the machine and disconnect the hoses.

What are the features of a hydraulic oil purification machine?

The hydraulic oil purification machine has many features that make it ideal for use in industrial settings, including:

1. Compact and portable design

The hydraulic oil purification machine is designed for easy portability and can be moved around as needed.

2. Automatic operation

The machine will start and stop automatically as needed, so you don’t have to worry about monitoring it constantly.

3. Easy to use

The machine is easy to set up and use, so you can get it up and running quickly.

4. Safe and reliable

The hydraulic oil purification machine is made with high-quality materials and components, so it is safe and reliable.

What are the standards of a hydraulic oil purification machine?

The hydraulic oil purification machine meets the following standards:

- ISO 9001

- ISO 14001

- CE

- SGS

- ROHS

- REACH

What are the precautions for using a hydraulic oil purification machine?

When using a hydraulic oil purification machine, please keep the following precautions in mind:

1. Do not use the machine in an environment with flammable or explosive vapours.

When you turn on the machine, it will heat the oil. If there are flammable or explosive vapours present, this could create a fire or explosion hazard.

2. Do not use the machine if the oil is highly viscous.

If the oil is too viscous, it will not flow through the machine properly and may cause damage.

3. Do not use the machine if the oil is contaminated with water.

If the oil is contaminated with water, it will not be purified properly and may cause damage to the machine.

4. Do not use the machine if the oil is dirty or cloudy.

If the oil is too dirty or cloudy, it will not be purified properly and may cause damage to the machine.

5. Do not use the machine if the oil level is low.

If the oil level is too low, it will not be purified properly and may cause damage to the machine.

6. Always disconnect the power supply before cleaning the machine.

Disconnecting the power supply will prevent the machine from turning on unexpectedly and causing injury.

7. Do not use harsh chemicals or solvents to clean the machine.

Harsh chemicals or solvents can damage the machine. Only use mild soap and water to clean it.

8. Always position the machine on a level surface.

If the machine is not level, it may not operate properly.

9. Do not use the machine if any parts are damaged.

If any parts are damaged, the machine will not operate properly and may cause injury.

10. Do not disassemble the machine.

Disassembling the machine can damage it and may cause injury. If you need to service the machine, please contact a qualified technician.

These simple guidelines will help you use the hydraulic oil purification machine safely and effectively.

Hydraulic oil purification machine operation steps.

- Connect the power supply and turn on the machine.

- Connect the inlet and outlet hoses to the machine.

- Add oil to the tank and start the pump.

- The machine will start purifying the oil automatically.

- When the process is finished, turn off the machine and disconnect the hoses.

Oil purification machine operation Introductions:

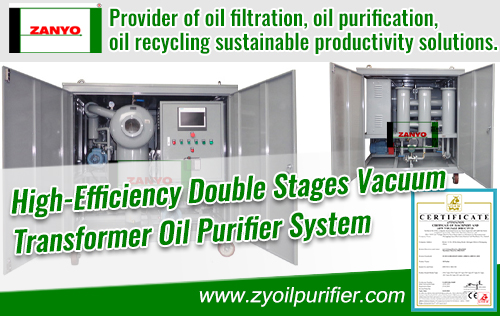

- This machine is used for treating hydraulic oil, lubricating oil, turbine oil, gear oil, compressor oil and other industrial oils.

- It can remove water, gas, impurities and sludge from the oils so they can be reused.

- The machine can extend the oils’ life and improve the machinery’s performance.

How does a hydraulic oil purification machine work?

The hydraulic oil purification machine uses a 3-stage filtration process to remove impurities from the oil.

1. The first stage is coarse filtration, removing large particles from the oil.

2. The second stage is fine filtration, which removes smaller particles from the oil.

3. The third stage is polishing, which gives the oil a bright, clean appearance.

What are the benefits of using a hydraulic oil purification machine?

There are many benefits to using a hydraulic oil purification machine, including:

1. Extending the life of the oil.

It is estimated that using a hydraulic oil purification machine can extend the life of the oil by 3-5 times.

2. Improving the performance of the machinery.

The purified oil will flow more easily and provide better lubrication for the moving parts, resulting in improved performance.

3. Reducing wear and tear on the machinery.

The purified oil will reduce friction and wear on the moving parts, resulting in less wear and tear on the machinery.

4. Reducing downtime.

If the machinery is well-lubricated, it will run more smoothly and have less downtime.

5. Saving money.

Using a hydraulic oil purification machine can save money in the long run by extending the life of the oil and reducing wear and tear on the machinery.

Hydraulic oil purification machine “stop” steps

- Please turn off the power supply and turn off the inlet and outlet valves.

- Please open the oil drain valve and start the oil pump to remove the oil from the tank.

- Please clean the machine with mild soap and water.

- Please disconnect the hoses from the machine.

- Please disconnect the power supply from the machine.

- Please store the machine in a cool, dry place.

Conclusion

Using a hydraulic oil purification machine is an effective way to extend the oil’s life and improve the machinery’s performance. Following the proper steps for operation and maintenance will ensure that the machine works properly and safely.