Hydraulic systems are utilized in a variety of industries as a means of exerting high levels of power. You will most commonly encounter such systems being used in machines such as excavators,  power steering systems, hydraulic brakes, garbage trucks, aircraft flight control systems, and various industrial machines.

power steering systems, hydraulic brakes, garbage trucks, aircraft flight control systems, and various industrial machines.

These systems make use of hydraulic oils or fluids as the medium by which power is transferred. They are suited for this purpose due to their zero compressibility qualities, meaning that any pressure exerted on them is transmitted at the rate of nearly 100 percent. Due to their importance, it is vital that they are kept as pure as possible, which is what HYDRAULIC OIL FILTRATION SYSTEMS are for.

HOW HYDRAULIC OIL FILTRATION SYSTEMS WORK

An effective OIL PURIFIER is designed to thoroughly eliminate any impurities that may contaminate hydraulic oil, turbine oil, aviation hydraulic oil, gear oil, anti-wear hydraulic oil, heat treatment oil, internal combustion engine oil, refrigerating oil, and more. Impurities include particulate matter, moisture, and gaseous substances. An OIL PURIFIER will help restore the oil’s viscosity, reduce acidity, restore its flashpoint, and generally make it capable of performing its functions optimally.

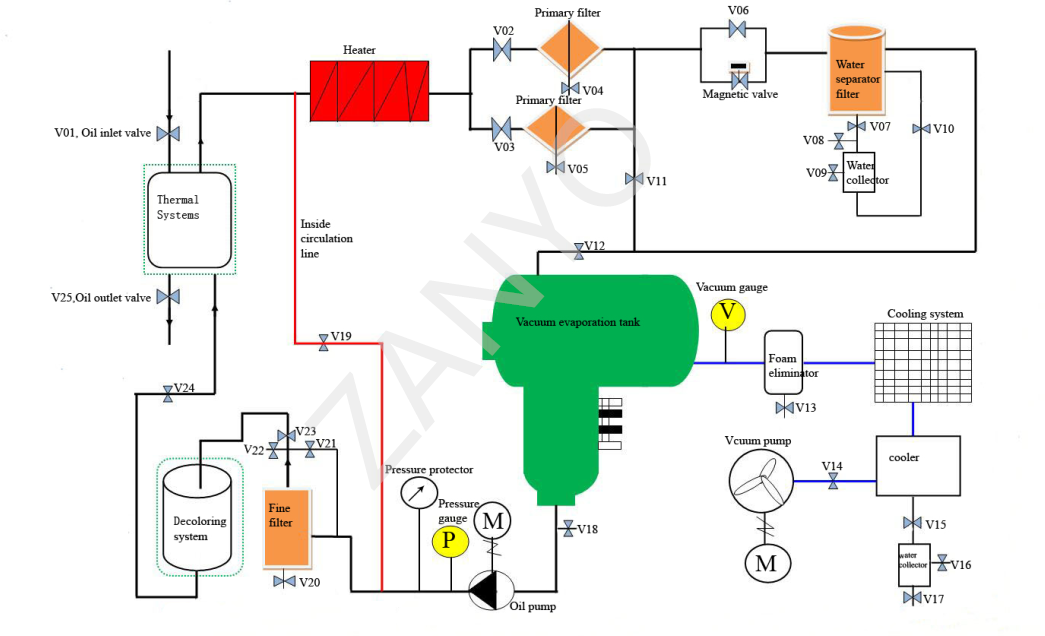

An oil filtration system works through a process involving several steps, as follows:

- The coarse or primary filter system will remove any larger impurities and particulate matter in the oil.

- The oil will then undergo a process of capillary condensation in what is known as a demulsifier system, where the demulsifying filter element will turn smaller droplets into larger ones.

- Moisture or water droplets will be removed from the oil through a vacuum system working in conjunction with a constant heat evaporating process. The vacuum pressure will pump out this moisture.

- The oil will then undergo a deacidification and decolorization process that is made possible by introducing molecular sorbents.

- It will then be put through what is known as an oil regeneration system for recycling.

- Finally, the oil will go through a fine filter system that will eliminate any microscopic impurities that the primary filtration system may not have dealt with.

An effective HYDRAULIC OIL FILTER MACHINE will be capable of removing impurities of sizes down to 1 micron, eliminate moisture down below 500 PPM, restore viscosity to within a range of between 10 CST to 680 CST, and generally achieve NAS-163 Class 6 standards. For best operational results, it is recommended that the following system configurations are made use of:

| OIL PUMPS: | Germany KRACHT, Tianjin Screw Oil Pump, Italy Seim Screw Oil Pump, etc. |

| VACUUM PUMPS: | Leybold, Busch, Hokaido, Atlas, Joysun, and others. |

| ELECTRICAL SYSTEMS: | Schneider, Siemens, etc. |

| OIL TESTERS: | Moisture Sensor, Flow Meter, BDV Oil Tester, etc. |

THE IMPORTANCE OF CLEAN HYDRAULIC OIL

The role that these oils play is vital to the operation of hydraulic systems. As such, these oils must be kept free of any impurities that may impair their effectiveness. While power transmission may be the most prominent function of these oils, they possess special qualities that allow them to play various other roles that are important as well to the overall performance and efficiency of the machinery in question, including:

- POWER TRANSFER MEDIUM: These oils have very low to zero compressibility, low volatility or flammability, a very low tendency to foam, and release any air trapped within them very quickly.

- HEAT TRANSFER MEDIUM: They make for highly effective conduits of heat energy due to their high thermal capacities and conductivity indexes.

- LUBRICATION AGENT: These oils will significantly help in the lubrication of your hydraulic machinery due to their thermal and oxidative stability; viscosity (film maintenance); filterability and cleanliness; demulsifier compatibility; water tolerance/hydrolytic stability; low-temperature fluidity; and general anti-wear characteristics.

- SEALING MEDIUM: The shear stability and high viscosity index of these oils make them effective sealing mediums.

- PUMP EFFICIENCY: Pumps will work at optimal capacities with the help of such oils thanks to their high viscosity indexes, which minimizes the chances and severity of any internal leakages.

- MACHINERY LONGEVITY: The compatibility of hydraulic oils with the metals and materials used in the system will help these machines last longer without experiencing corrosion or mechanical wear.

- SPECIAL FUNCTIONS: Certain types of hydraulic oils may be employed for specialized functions, including friction modifications, radiation mitigation, and fire resistance.

Impurities such as free carbon, metal particles, gas bubbles, and other particulates have various harmful effects, not only on a machine or system’s performance and running costs but its overall condition. These effects include:

- IMPAIRED PERFORMANCE: With reduced power transmission, for example, a backhoe will not exert power at optimal levels, making work harder and more costly.

- DAMAGE TO THE MACHINE: Poor hydraulic oil quality might leave your systems and machinery vulnerable to the harmful effects of corrosion, mechanical wear, leakages, and more.

- ACCELERATED OIL OXIDATION: The presence of air bubbles in your oil might cause it to become oxidized, meaning that it will need to be changed much sooner than it otherwise would have since it will lose the properties that make it effective.

- LUBRICATION SYSTEM IMPAIRMENT: When hydraulic oils fail in their lubricating function, the machines and systems they protect will be vulnerable to mechanical wear and potential breakdown.

OIL FILTRATION SYSTEMS can eliminate these negative elements and ensure that your machinery and hydraulic systems are in perfect working condition and capable of working at maximum efficiency for many years. Note that maintaining pure oil standards is one of the ways in which operators can minimize the negative environmental impact of heavy machinery and systems.

GET IN TOUCH WITH ZANYO TODAY

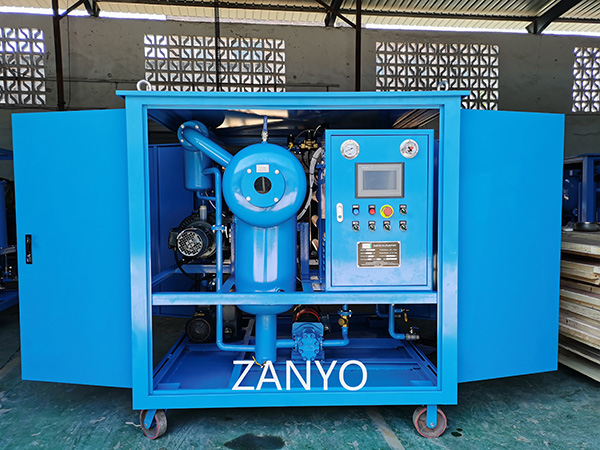

Hydraulic OIL FILTRATION SYSTEMS are highly effective and useful in mining, transport, manufacture, transportation, metallurgy, food processing, and a host of others. While keeping your hydraulic oil clean and free of impurities will always positively affect your bottom line, you need to ensure that the HYDRAULIC OIL FILTER MACHINE you utilize is of the highest quality and effectiveness.

You can rely on us to deliver OIL FILTER MACHINES that are durable, efficient, and powerfully effective. China Supply is a worldwide oil purification system provider and is capable of serving clients from all over the world. Call us today, and we’ll help you figure out the right solution for your needs.